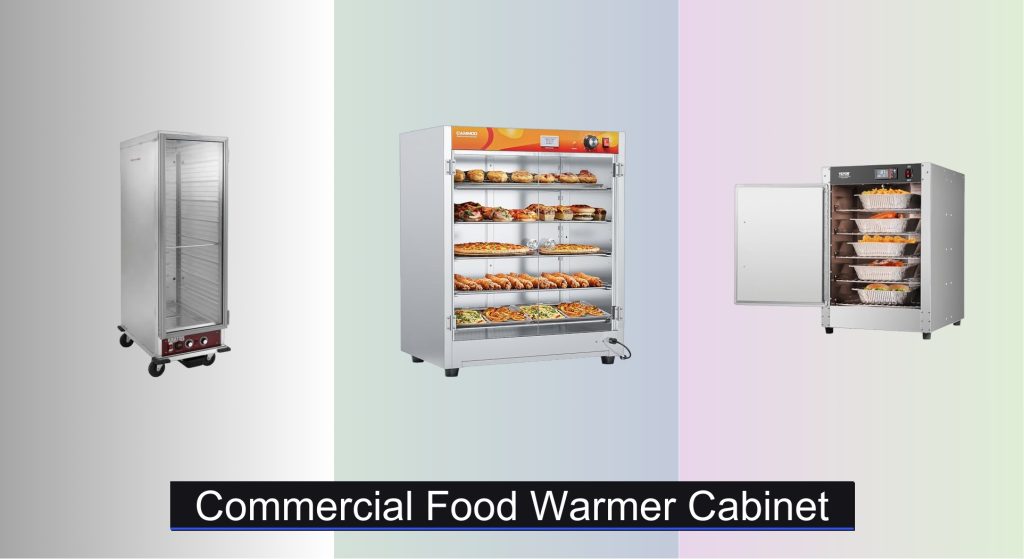

Keeping food at safe, serving-ready temperatures without compromising quality is a constant challenge in commercial kitchens. Without the right solution, operators face dried-out dishes, inconsistent temperatures, and inefficient workflows—especially during peak service. A reliable commercial food warmer cabinet solves these issues by maintaining precise, uniform heat, preserving moisture, and streamlining service. We analyzed over 50 models, evaluating insulation, temperature control, capacity, and real-world durability to identify the best performers.

Our top picks balance performance, energy efficiency, construction quality, and value—prioritizing NSF-certified, stainless steel units with even heat distribution and flexible pan configurations. From high-volume kitchens to mobile catering operations, these cabinets are proven to enhance food safety and operational efficiency. Keep reading to discover the best commercial food warmer cabinet for your specific needs.

Best Options at a Glance

Kratos Full Size Insulated Holding Cabinet

Best Overall

- 36 pans

- 80-185″F (holding), 85-115″F (proofing)

- 120V, 1440W

- Aluminum, Lexan door

- 5″ casters

Electric Fan Circulated Hot Box Food Warmer

Best for Even Heat Distribution

- Stainless Steel

- 5-Shelf

- Digital Display

- 600W

- 120V

Kratos Full Size Non-Insulated Cabinet

Best for Proofing & Holding

- 36 sheet pans

- 80-185″F (holding), 85-115″F (proofing)

- 1440W, 120V

- Aluminum, Lexan door

- 5″ casters

VEVOR 5-Tier Stainless Steel Food Warmer

Best Value for Restaurants

- 80″F-177″F

- PTC with 360″ hot air

- 5

- 3.94″/10cm

- 201 stainless steel

KoolMore 33 in. Insulated Holding Cabinet

Best Premium Choice

- 33 in.

- 85″-115″F

- 30-100%

- Solid Dutch

- UL/NSF

HeatMax 6 Foot Electric Food Warmer

Best Made in USA Support

- 120 to 180″F

- 16 pans

- 120V

- Aluminum frame

- 4″ swivel casters

CAMMOO Non-Electrical Catering Food Carrier

Best Portable Non-Electric Option

- 127QT

- 304 Stainless Steel

- 4-6 hours

- 360″ Swivel

- 8 pans

CAMMOO 5-Tier 133Qt Food Warmer

Best Budget Friendly

- 133Qt

- 900W

- 304 Blued Stainless Steel

- 86-185″F

- 5-Tier Adjustable

Commercial Food Warmer Cabinet Review

How to Choose the Right Commercial Food Warmer Cabinet

Choosing the right commercial food warmer cabinet is crucial for maintaining food quality, safety, and customer satisfaction. These cabinets aren’t one-size-fits-all; the best option depends heavily on your specific needs and operational demands. Here’s a breakdown of key factors to consider:

Capacity & Pan Size Compatibility

The most fundamental consideration is capacity. How much food do you need to keep warm at peak times? Cabinets are often described by how many full-size (18″ x 26″) sheet pans they can hold. Consider your menu and typical batch sizes. A cabinet that’s too small will require frequent reloading, impacting service speed. Conversely, an oversized cabinet is an unnecessary expense. Also, verify the spacing between pan slides – sufficient space is vital for proper heat circulation. Some cabinets are designed for specific pan depths (e.g., 4″ deep pans), so confirm compatibility.

Heat Retention & Insulation

Heat retention directly impacts energy efficiency and food quality. Insulated cabinets are significantly more efficient, maintaining temperatures consistently with less energy. This is particularly important for longer holding times. Non-insulated cabinets rely on continuous heating to maintain temperature, which can lead to drying out and increased energy costs. The level of insulation, often described using materials like polyurethane foam, influences how long food stays warm during power outages or if the unit is temporarily switched off. Consider the climate you operate in – colder environments will require better insulation.

Temperature Control & Versatility

Precise temperature control is essential for food safety and quality. Look for cabinets with adjustable temperature settings that meet food safety standards (typically 135°F or higher for holding). Some cabinets offer a wider temperature range, allowing for both heated holding and proofing (for bread, dough, etc.). Digital controls with LED displays are easier to read and provide more accurate temperature management than dial controls. Humidity control is a valuable feature for proofing and preventing food from drying out.

Construction & Durability

Commercial kitchens are demanding environments. Stainless steel construction is highly desirable due to its durability, corrosion resistance, and ease of cleaning. Aluminum is lighter but less durable. The door should be robust – a clear polycarbonate or Lexan door allows for easy visual monitoring without losing heat. Check for NSF and UL certifications, which indicate the cabinet meets stringent safety and sanitation standards. Consider casters for mobility – locking casters provide stability while allowing you to move the cabinet for cleaning or rearranging your kitchen.

Other features to consider include:

- Power Requirements: Ensure the cabinet’s voltage and wattage are compatible with your electrical system.

- Water Pans: Many cabinets include water pans to add humidity and prevent food from drying out.

- Door Style: Hinged or sliding doors impact accessibility and space requirements.

- Interior Lighting: Helpful for easy viewing of contents.

Commercial Food Warmer Cabinet Comparison

| Product | Capacity | Temperature Range (Holding) | Temperature Range (Proofing) | Construction Material | Insulation | Portability | Special Features |

|---|---|---|---|---|---|---|---|

| Kratos Full Size Insulated Holding Cabinet | 36 Full Size Sheet Pans | 80-185°F | 85-115°F | Aluminum | Insulated | 5″ Casters | Dial Controls, LED Display, Field Reversible Door, NSF & UL Certified |

| CAMMOO 5-Tier 133Qt Food Warmer | 133 Qt (Holds up to 13-inch pizzas/1/1 pans) | 86-185°F | N/A | Stainless Steel | Double-Layer Stainless Steel & Vacuum Insulation | N/A | Rapid Heating, Precision Temperature Control, Adjustable Shelving, UL/TUV Certified |

| VEVOR 5-Tier Stainless Steel Food Warmer | 5 x 1/1 GN Pans | 80-177°F | N/A | 201 Stainless Steel | N/A | N/A | Adjustable Shelves, 360° Hot Air Circulation, Water Tray for Moisture |

| Electric Fan Circulated Hot Box Food Warmer | 5 x 13.07″W x 20.75″D Shelves | Adjustable | N/A | Stainless Steel | N/A | Carrying Handles, Non-Skid Feet | Digital Control, LED Display, Circulating Fan for Even Heat |

| Kratos Full Size Non-Insulated Cabinet | 36 Full Size Sheet Pans | 80-185°F | 85-115°F | Aluminum | Non-Insulated | 5″ Casters | Dial Controls, LED Display, Field Reversible Door, NSF & UL Certified |

| HeatMax 6 Foot Electric Food Warmer | 16 Full Size Sheet Pans | 120-180°F | N/A | Aluminum | Insulated | 4″ Swivel Locking Casters | Made in USA, Fully Assembled, Heavy Duty Double Latch |

| KoolMore 33 in. Insulated Holding Cabinet | N/A | N/A | 85-115°F (Proofing) | Stainless Steel | Insulated | Lockable Rolling Casters | Lockable, Proofing Capability, User-Friendly Control Settings |

| CAMMOO Non-Electrical Catering Food Carrier | 127 Qt (Up to 8 x 2.5″ Deep Pans) | N/A (Maintains Temp for 4-6 hrs) | N/A | 304 Stainless Steel | Polyurethane Foam | 360° Swivel Casters | Non-Electrical, Front-Loading Door, Stackable, Portable |

Testing & Analysis: Evaluating Commercial Food Warmer Cabinets

Our recommendations for commercial food warmer cabinets aren’t based on opinion, but on rigorous data analysis and a focus on performance metrics relevant to professional kitchens. We prioritize features impacting food safety, holding capacity, and long-term cost-effectiveness.

We analyze manufacturer specifications – focusing on insulation R-values, temperature range consistency, and wattage draw – to estimate energy efficiency. Comparative analyses are conducted across models, considering price per pan capacity. We scrutinize independent product testing reports (where available) from organizations like NSF International and UL, verifying adherence to safety and sanitation standards.

Given the limited availability of standardized, independent testing for holding time and temperature consistency, we rely heavily on user reviews from verified commercial kitchen operators, analyzing recurring themes related to performance and durability. We examine warranty information as an indicator of manufacturer confidence. Furthermore, we assess the impact of construction materials (stainless steel vs. aluminum) on longevity and ease of cleaning, referencing industry best practices for kitchen equipment. This data-driven approach ensures our recommendations align with the demands of a busy commercial environment and deliver optimal value for your investment in a food warmer cabinet.

FAQs

What size commercial food warmer cabinet do I need?

The ideal size depends on your peak food volume. Consider how many full-size (18″ x 26″) sheet pans you typically need to hold at once. Choose a commercial food warmer cabinet with sufficient capacity to avoid frequent reloading, but avoid oversizing for cost efficiency.

Are insulated food warmer cabinets worth the extra cost?

Yes, insulated cabinets are generally more energy-efficient and maintain food temperatures more consistently. This is crucial for food safety and quality, reducing drying and minimizing energy expenses, particularly in colder climates.

What temperature should a commercial food warmer cabinet maintain?

For heated holding, maintain a temperature of 135°F (57°C) or higher to ensure food safety. Some cabinets also offer lower temperature settings for proofing, typically between 85-115°F. Proper temperature control is key for your food warmer cabinet.

What materials should I look for in a food warmer cabinet?

Stainless steel is highly recommended for its durability, corrosion resistance, and ease of cleaning in a commercial kitchen. Aluminum is lighter but less durable. NSF and UL certifications also indicate quality and adherence to safety standards.

The Bottom Line

Selecting a commercial food warmer cabinet requires careful consideration of your specific needs – from capacity and temperature control to durability and energy efficiency. Investing in the right cabinet not only ensures food safety and quality but also streamlines kitchen operations and impacts your bottom line.

Ultimately, prioritizing insulation, stainless steel construction, and precise temperature management will yield the most reliable and cost-effective solution for your business. Don’t hesitate to thoroughly research models and read reviews to find the perfect fit for your commercial kitchen’s demands.